|

Quick Turn-Around Mold Design and

Delivery

(blue text are active links)

The following jobs we delivered

within two weeks or less.

- Tempo

specializes in delivering rapid turn-around jobs -

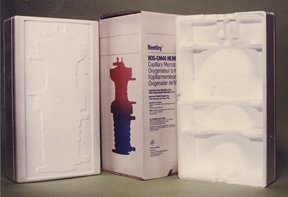

Blood Oxygenator package for American Bentley Laboratories

This customized box with ribs for membrane blood oxygenators fits inside a

specially printed corrugated box with blue ink turning to red to symbolize the

function of an oxygenator in providing oxygen to the bloodstream as our lungs

do. Rush two week delivery contract

was accomplished with an extra day to spare, including the mold engraving

showing silhouette of the oxygenator on the box surface.

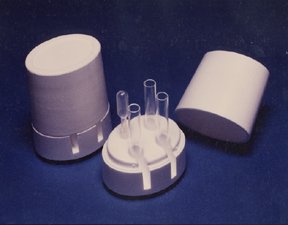

Test Kit produced for Becton Dickinson

Test

kit for Becton Dickinson with windows to observe color change in the test tubes

facing front. This is another

example of two week mold construction and delivery to assist with expedited

product launch.

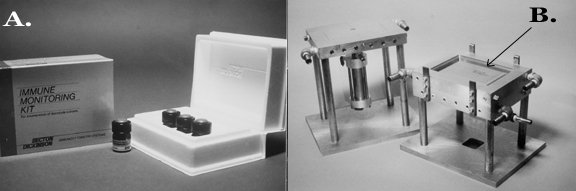

Immune Monitoring Kit made for Becton Dickinson

A.

This

attractive kit is molded from high density EPS and laminated to colorful printed

chipboard to present a book-style hinged kit for multiple uses.

B.

Machined

aluminum plate is used to make molds. The

metal is honeycombed with drilled circulation channels for heating and cooling

the metal. Connections for steam

and water are attached. The filler

uses a venturi principle to blow the ambient temperature EPS beads into the mold

cavity, it is shown attached to the flat back-plate on left.

Molds bake the polystyrene plastic into the desired shape, in this case a

test kit for Becton Dickinson shown in A, note the mold engraving on right which

creates the logo on the inside cover of the kit.

Tempo can make single cavity molds like this for your customized

requirement, for small or rapid turnaround delivery.

For larger volume molding applications additional mold cavities can be

added when needed.

|