|

|

Tempo Plastic Co., Inc., provides stock

and custom protective packaging, particulate free, semi-flexible, long life protection for archival storage, in-house handling, or shipping.

We also provide cleanroom - compatible, durable parts molded from copolymer foams, test reports for liquid particle counts and organic analysis are posted.

We feature thin walls, smooth surfaces, high foam densities,

which can be replacements for injection molded parts.

We specialize in intricate shapes and offer static dissipative certification, responsiveness and low cost molds. |

|

|

|

Award Winning

Designs

(blue text are active links) |

|

Home Heating/Water Heating Burner

Irish Foundry & Manufacturing,

Seattle, Washington

Metal: A356 aluminum with T6 heat treatment.

Casting Process: Lost foam.

Weight: 3 lbs.

Dimensions: 8 x 1.5 in.

Application: For use in home-heating/water-heating systems.

-

Due to the integral ring design, removal of the air-set core

that was supported by chaplets in the original sand casting

design was extremely difficult. Conversion to the lost foam

process eliminated the need for cores and chaplet.

-

Utilizing liquid flow patterns, the 211 gas burner holes, which

have a diameter of 0.125 in. and a length of 0.34 in., were

cast-in to eliminate machining.

Source: Engineer Casting Solutions,

Summer 2004 (

www.castsolutions.com ) |

|

|

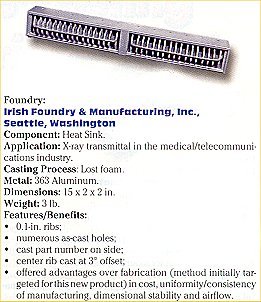

The cast above was one

of 10 components recognized for "ingenuity in design,

casting quality, functional benefits and overall contribution to

expanding the market for metal casting."

Tempo produced the foam pattern to make this thin wall casting.

Source:

Modern Casting Magazine, June 2001 |

|

|

|