|

|

|

SYNBRA - Thin Wall

Copolymers

Chemically Resistant, High Temperature

Performance

(blue text are active links)

(Adobe

Reader Required)

| Images: |

|

|

|

|

|

|

| . |

Tempo's unique thin wall molding

methods allow processing new High Temperature expandable engineering resins

where tailored mechanical and temperature performance, functionality and light

weight are critical requirements. These foam materials offer the designer

excellent strength-to-weight ratios.

Tempo specializes in complex shapes with molded-in functionality such as metal

and plastic inserts. No draft conditions and molded undercuts are possible

with Tempo's self contained mold design.

Tempo can mold wall transitions and intersections without the sink problems

common to injection molding.

Now available in North America, Synbra Technology bv offers Hi Temp PPO/EPS

material, produced in Holland, these HT products are based on NORYL©

Resin supplied by SABIC Innovative Plastics.

Applied as expandable foam, the HT-EPS is a replacement for Dytherm/Caril/GECET

and finds application in specialty floats, steam sterilisable trays, insulation,

lightweight supports, and for automobile parts that require good energy

absorption properties, heat resistance and dimensional stability.

The Synbra Technology bv material is unaffected by alkali solutions and is

resistant to mineral acidic acids and their water solutions and diesel fuels.

Synbra Technology bv HT resin bum rate will satisfy the standards set forth in

MVSS 302. |

| . |

|

Tempo’s patented

Dry Molding Process is ideal for thin wall molding (under 6mm thickness) for

SYNBRA Hi Temp which is a very stiff material, not smooth flowing inside mold geometry.

Tempo’s Open Architecture mold construction allows for molded undercuts and

no-draft conditions where designs require. Customers save significant mold costs

as Tempo machinery accommodates single and double cavity molds for early

production phases, with additional capacity added as needed.

SYNBRA Hi Temp is chemically resistant to virtually all aqueous media including

dilute acids and alkalis. SYNBRA Hi Temp is resistant to water-miscible alcohols

such as methanol, ethanol, i-propanol and also to silicone oils.

SYNBRA Hi Temp has successfully tested for 30 days immersed in #1 Diesel (kerosene),

it has limited resistance to paraffin oils, #2 Diesel and Vaseline. These

substances may attack the surface of foamed materials after long-term

contact and may cause deformation through shrinkage.

Click (synbra_eer_info.pdf

- 2577kb) to see a table showing resistance of SYNBRA Hi Temp to the most common

chemical substances.

Click the Lab testing reports for

SYNBRA Hi Temp and

Static Dissipative

SYNBRA Hi Temp. |

| . |

| Links: |

| 1)

Specification Sheet: EPS HT Grades - September 2012 |

2)

High Temperature Foams for Design (pdf

2200kb)

|

| . |

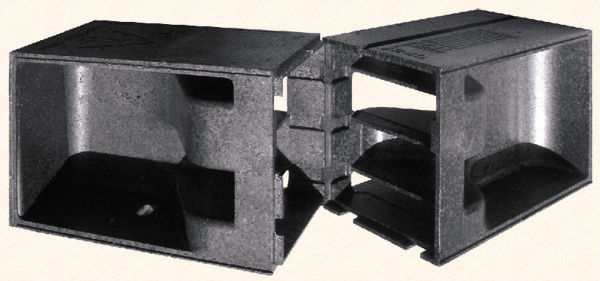

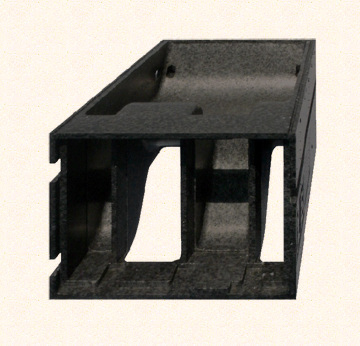

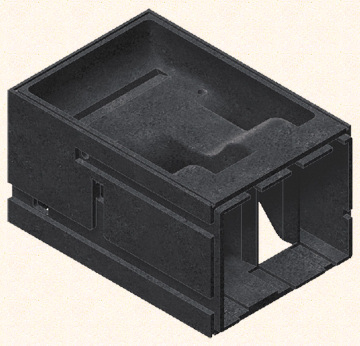

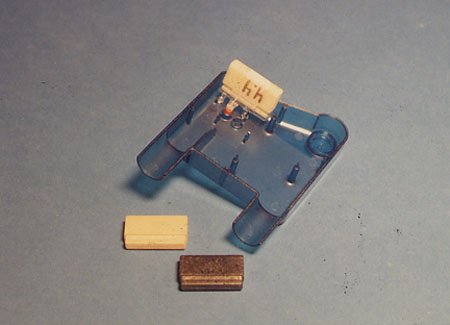

| Details on all four exterior walls

require each side wall of the mold to retract. Heat controls for every

mold segment allow adjustment for nice surface finish.

3mm wall thickness for interlocks on these mating duct sections. SYNBRA

Hi Temp

samples on right, high density UL-94 EPS on left. |

|

Rittal Corp:

Press Release 08-2009

Rittal Corp:

Industrial News

2009 - Thermoelectric Coolers

Open Architecture Mold Design

- Video

|

|

| |

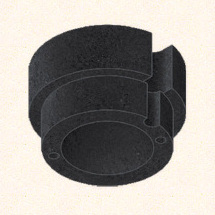

High temperature floats for Inspiron Respiratory

bedside humidifier. Evaluation of foamed polycarbonate and NOREL™ showed

excessive weight. Tempo provided SYNBRA Hi Temp F-100 copolymer foam solution half

the weight of the foamed injection resins.

These floats are sized 40.6mm x 22.8mm x 6.3mm (1.6” x .9” x .25”), with 5mm

thick neck to fit into slide holder, (note orange valve attached to slide holder

in photo) |

|

|

|

| |

|

This four cavity aluminum

mold saved Inspiron Respiratory $thousands compared with the injection

molds made for testing floats molded from high temperature foamed

injection resins. |

|

|

|

|