Tempo pioneered the foam cup market on the US west coast in 1960. Major contracts with LA City Schools and Sweetheart Cup kept the company busy until diversification out of food service in the 1970’s. US Patents on Tempo’s DRY molding process were finally granted in 1965. Mold making technology has advanced far beyond the Bridgeport Mill and Deckel Pantograph since then.

Tempo can use your hand made prototype to engineer a production mold even if no CAD (computer aided design) files are available. Tempo can also accept CAD files in all formats for rapid product development.

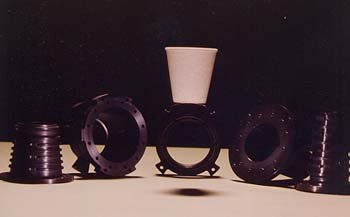

Picture 1-2: Foam cup mold shows steam jacketing for fusion of no leak cups.

Picture 3: Shows Teflon volume displacers to direct steam where heat is needed for fast cycling cup mold.

Picture 4: Tempo Dry Mold cup technology features steam jacketed molds for even heat distribution and smooth glossy surface finish.

Links: About Us

|

|

|

|