Full Range of Competence

Modular molds can be fitted with new inserts for low cost customization.

Insert molding is totally unique.

With insert molding, we can mold an anodized aluminum part inside a foam cartridge. This is used for Rapid DNA Technology, which can be used by law enforcement to solve and prevent crimes, to exonerate the innocent, and to prevent DNA analysis backlogs. This assembly shows black anodized aluminum part peeking from our white cartridge, that touches a cooling system to keep the big syringe cold so the DNA chemistry is kept “fresh”. Insert molding shows Tempo’s cool competence with tricky projects.

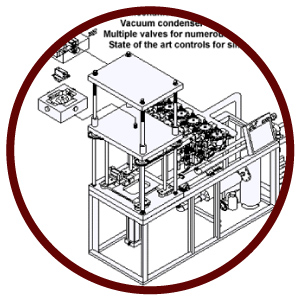

Customized foam molding machinery for your in-house production

Tempo’s dry molding process uses small molding machines. Single and double mold cavities can often meet your production requirements with low overall mold investment.

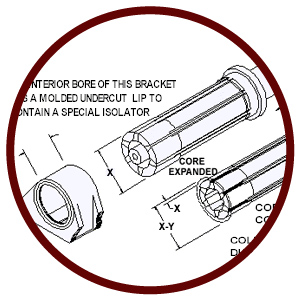

Molded Undercuts for one piece components

The Collapsible core shows the ability to mold products with inner molded requirements. Below is an example of how the Collapsible core was used to mold an inner lip on a Diesel truck bracket.

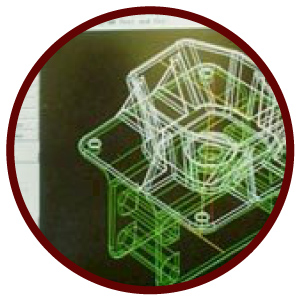

Computer Language is Transferable Between All Formats

This bracket requires twelve separately heated mold sections. It was previously made as a weldment but converted to a Lost Foam aluminum casting

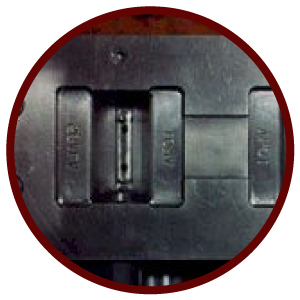

Retraction Slides

Precision machined aluminum plate molds with dual steam circulation for even temperature control. Multiple retraction slides within machined guides for continued true alignment.

Wall Thickness

Even wall thickness, hollow molds (reverse side of mold wall seen), dual steam circulation for even temperature controls

3D

Full and complete 3d surface and contouring capabilities.

Precision

Precision machined, self-contained molds with dual stream circulation for even temperature control. No-Draft cores pulled by solid-mount cylinders for repeatable true alignment.

Alignment

Mold alignment pins provide true positioning, preventing mismatched parting lines.

Cooling

Heat Circulation Drilled for even part cooling.